The 43/0.4kV Oil Immersed Distribution Transformer is a critical component in modern power systems, enabling efficient voltage step-down from 10kV, 35kV, or 6kV grids to the standard user-end voltage of 230V/400V. This three-phase transformer supports up to 2500kVA and is designed for use in both indoor and outdoor environments. For transformers ≤315kVA, pole-mounted installations are also feasible.

Built for a standard frequency of 50Hz or 60Hz, it operates effectively within temperatures from -25°C to +40°C, and up to 1000 meters altitude. The robust insulation and reliable oil-immersed design make this transformer an ideal choice for industrial, residential, and utility-scale applications.

Technical Specifications

| Rated Capacity (kVA) | High Voltage (kV) | Tapping Range | Low Voltage (kV) | No-load Loss (W) | Load Loss (W) | No-load Current (A) |

|---|

| 50 | 35 | ±5%, ±2×2.5% | 0.4 | 450 | 1420 | 1.6 |

| 100 | | | | 630 | 2099 | 1.4 |

| 160 | | | | 790 | 2810 | 1.3 |

| 200 | | | | 880 | 3320 | 1.2 |

| 250 | | | | 990 | 3800 | 1.1 |

| 315 | | | | 1170 | 4510 | 1.1 |

| 400 | | | | 1370 | 5410 | 1.0 |

| 500 | | | | 1620 | 6650 | 1.0 |

| 630 | | | | 1860 | 7690 | 0.9 |

| 800 | | | | 2160 | 9120 | 0.8 |

| 1000 | | | | 2430 | 10400 | 0.8 |

| 1250 | | | | 2830 | 12700 | 0.7 |

| 1600 | | | | 3240 | 15400 | 0.6 |

| 2000 | | | | 3820 | 18200 | 0.6 |

| 2500 | | | | 4455 | 21800 | 0.5 |

The oil-immersed design offers an excellent balance between cost-effectiveness and insulation performance. Transformer oil not only dissipates heat efficiently but also prolongs equipment life by protecting internal components from oxidation and moisture.

Historical Insight

This design concept dates back to the late 1800s and has remained a cornerstone in electrical infrastructure thanks to its simplicity, robustness, and performance.

Key Benefits:

- Excellent cooling through transformer oil

- High reliability and long service life

- Suitable for pole-mount and ground installation

- Compatible with harsh weather and high-humidity environments

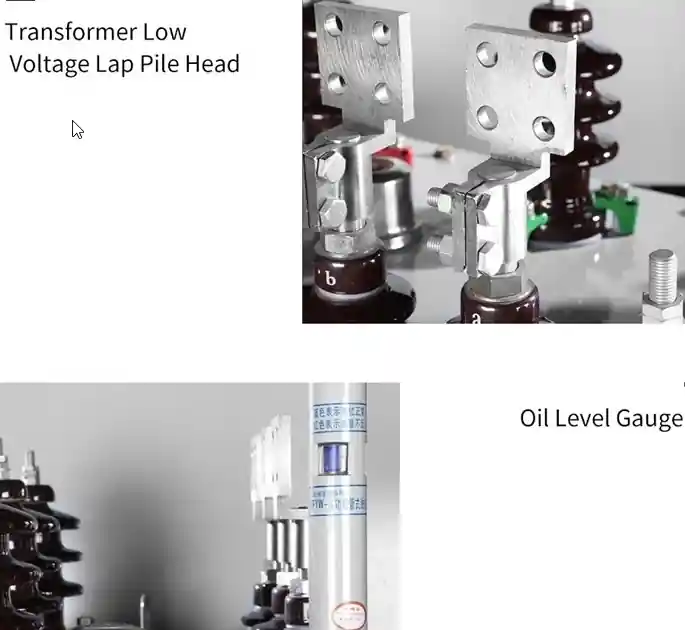

Construction and Design Features

- Core: Built from cold-rolled silicon steel with high magnetic permeability to minimize core losses.

- Winding: Made with high-purity copper in concentric or layered structures; ensures balanced magnetic flux and resistance to short-circuit forces.

- Tank: Corrugated steel shell eliminates the need for an expansion tank while supporting breathing under thermal changes.

- Oil Processing: Vacuum-dried coil and core; oil injected using vacuum filtration to ensure low moisture content.

- Sealing: Hermetically sealed tank to prevent ingress of moisture and oxygen, extending insulation life.

A: The key difference lies in the cooling medium. Oil-immersed transformers use transformer oil for insulation and cooling, offering higher capacity and better thermal performance, while dry-type units are more eco-friendly and suited for indoor use.

A: Absolutely. These transformers are often installed outdoors, even in harsh environments, thanks to their sealed tank design that prevents environmental ingress.

A: With high-quality sealing and low moisture ingress, transformer oil in modern units rarely needs replacement under normal operating conditions, often lasting decades.

Key Advantages

- Low partial discharge and low noise operation

- Maintenance-free operation

- Resistant to moisture and environmental damage

- Long-lasting insulation performance

- Compact installation footprint