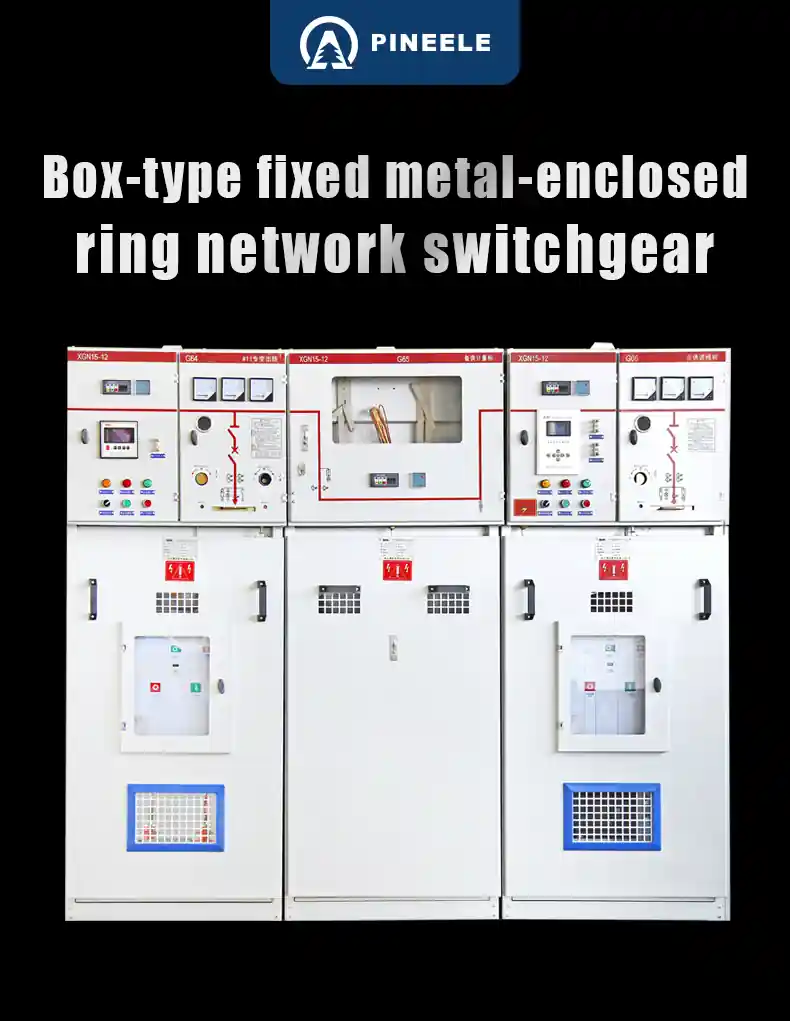

TheXGN15-12~24Ring Main Unit guideis a fully modular, metal-enclosed, air-tight switchgear solution designed for high-performance power distribution at12kV and 24kVvoltage levels. FeaturingSF6 gas insulation, superior mechanical interlocking, and high environmental adaptability, the XGN15 RMU is widely used in medium-voltage distribution networks for its safety, compact design, and intelligent automation capabilities.

Technical Parameters of XGN15-12~24 Ring Main Unit

| Specification | 12kV Version | 24kV Version |

|---|

| Rated Voltage | 12kV | 24kV |

| Rated Frequency | 50/60Hz | 50/60Hz |

| Main Busbar Rated Current | 630A | 630A |

| Branch Busbar Rated Current | 630A / 125A (fuse-limited) | 630A / ≤100A (fuse combination) |

| Power Frequency Withstand Voltage | 42kV | 65kV |

| Impulse Withstand Voltage | 75kV | 85kV |

| Short-Time Withstand Current | 20kA/3s | 25kA/2s |

| Peak Withstand Current | 50kA | 63kA |

| Short-Circuit Making Current | 50kA | 50kA |

| Short-Circuit Breaking Current | 31.5kA (CB cabinet) | 31.5kA |

| Load Break Current | 630A | 630A |

| Cable Charging Current | 10A | 25A |

| Mechanical Life (Load Switch) | 5000 times | 3000 times |

| Mechanical Life (Grounding Switch) | 2000 times | 2000 times |

| Protection Level | IP3X | IP3X |

| Structure Type | Modular / Metal-enclosed | Modular / Metal-enclosed |

| Insulation Medium | SF6 Gas | SF6 Gas |

Structural Highlights

Busbar Room

- Located at the upper part of the cabinet, connecting all units in the switchgear row.

Load Switch Compartment

- Built withepoxy resin cast columnsfilled with SF6 gas for insulation.

- Optional gas density meter or alarm contact display available.

Cable Room

- Spacious layout allows easy installation of cables, lightning arresters, current transformers, and grounding switches.

- Lower chamber sealed with rubber gasket to prevent moisture and small animals.

Low-Voltage Control & Mechanism

- Mechanical interlocking and spring operating mechanisms built-in.

- Auxiliary accessories: capacitive indicators, trip coils, auxiliary contacts, relays, control circuits.

- For 750mm wide cabinets, dual low-voltage rooms can hold additional automation gear.

Dimensions (Overall & Mounting)

| Configuration | Height (mm) | Width (mm) | Depth (mm) |

|---|

| XGN15-12 Standard | Custom | 750 | Standard |

| XGN15-24 Configuration | Custom | 750 | Standard |

(Exact cabinet size and layout can be customized per your project.)

Operating Conditions

| Environment Factor | Specification |

|---|

| Ambient Temperature | -15°C to +40°C |

| Daily Avg. Temperature | ≤35°C |

| Altitude | ≤1000m |

| Relative Humidity (Daily / Monthly) | ≤95% / ≤90% |

| Vapor Pressure (Daily / Monthly) | ≤2.2kPa / ≤1.8kPa |

| Seismic Intensity | ≤ Magnitude 8 |

| Environmental Limitations | No corrosive or flammable gas |

Packaging & Delivery

- Packed inreinforced wooden caseswith internal cushioning.

- Suitable for long-distancesea and air transport.

- Custom switchgear layout and accessories can be pre-configured based on order.

Application Scenarios

- Urban secondary substations

- Industrial plant power systems

- Renewable energy microgrids

- Public infrastructure projects

- Smart grid distribution networks

Frequently Asked Questions

Q1: What’s the advantage of the modular design in the XGN15-12~24 RMU?

A:It allows flexible unit combination, fast expansion, and convenient maintenance, making it ideal for scalable networks.

Q2: Can thisRMU guidebe equipped with remote monitoring or automation?

A:Yes, it supports motorized operation, control terminals, and SCADA integration.

Q3: Is the SF6 gas fully sealed inside the unit?

A:Yes, the gas-insulated chamber is completely sealed and pressure-tested to ensure long-term operation without leakage.